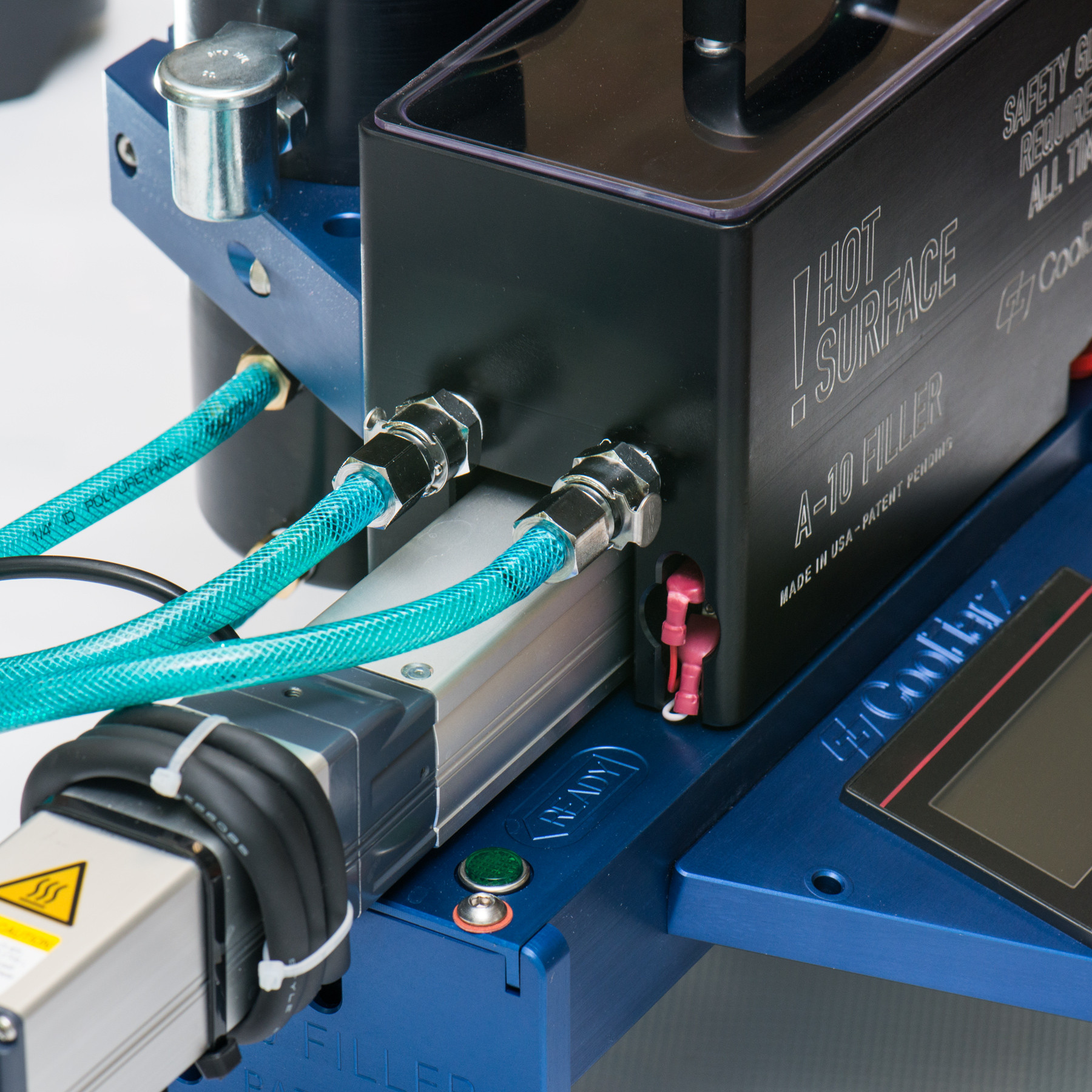

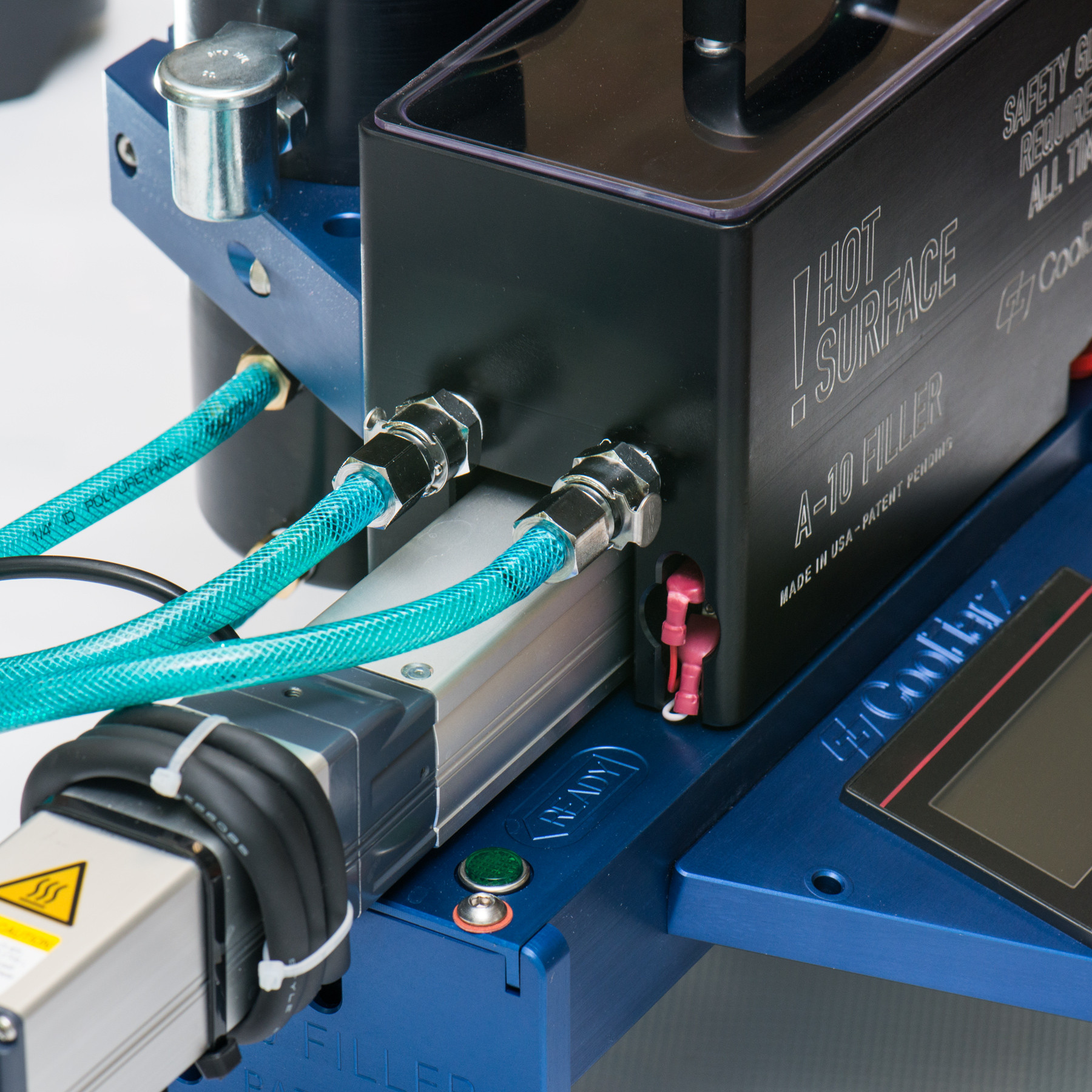

Part Number: A-10 FILLER

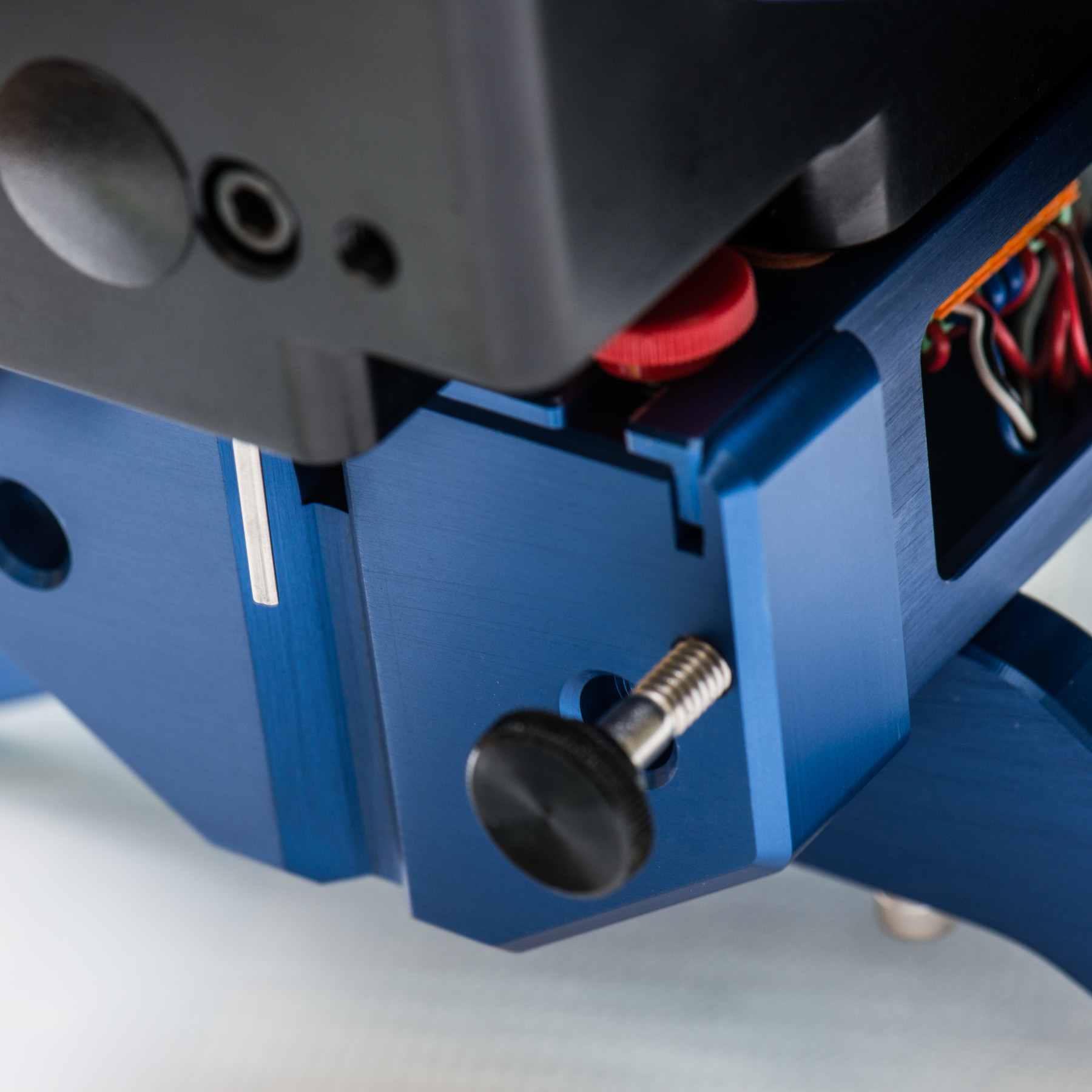

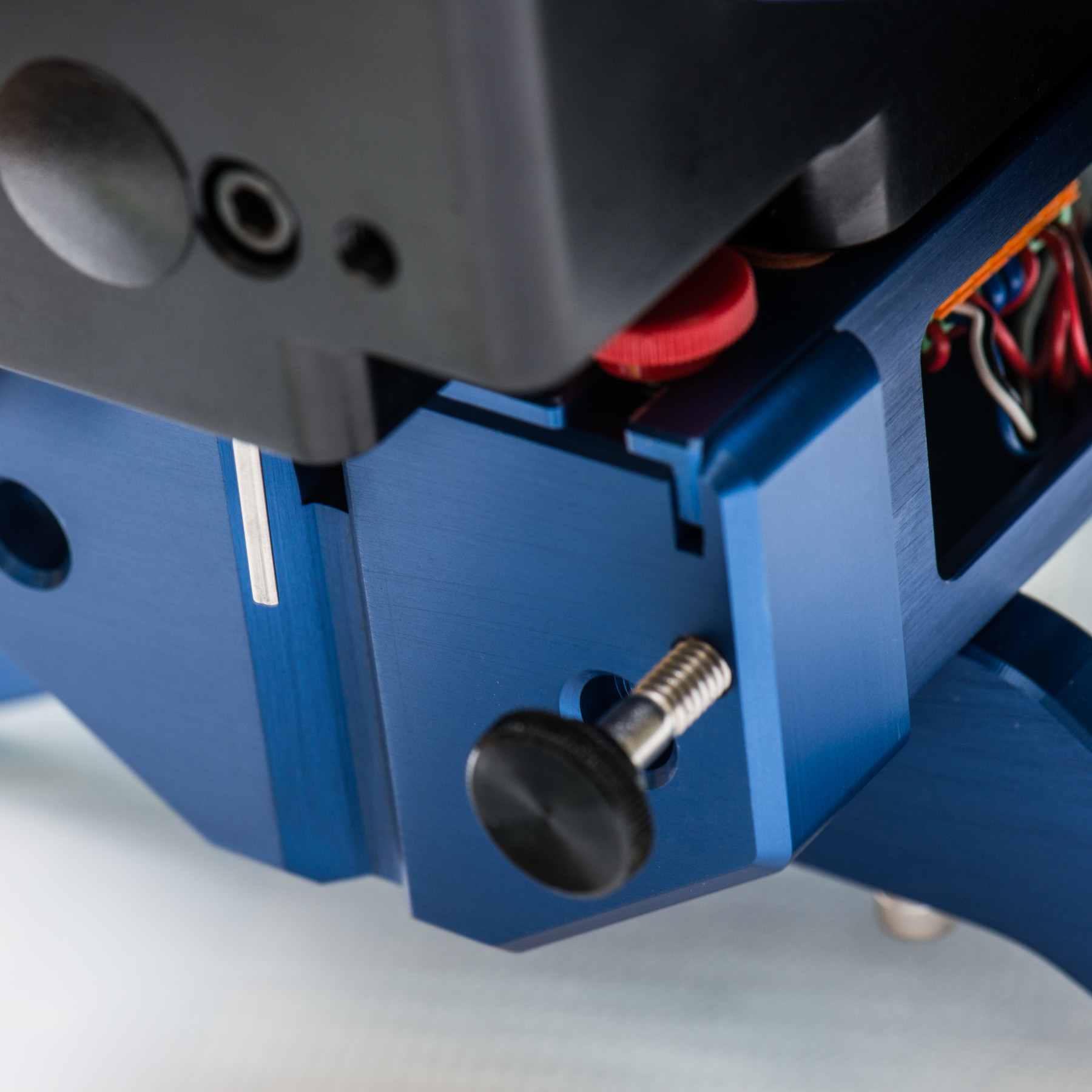

Cooljarz A-10 Filler™ Precision Cartridge Filling Machine

$ 16,100.00

$ 16,100.00 x 1

Quantity

Cooljarz

Please Wait...

Part Number: A-10 FILLER

$ 16,100.00

$ 16,100.00 x 1

Quantity

Cooljarz™ A-10 Cartridge Filler is a compact precision filling machine for oils and concentrates. Fill any cartridge, vape pen or syringe, mess-free, with as little waste as possible. The A-10 Filler has now been discontinued. Cooljarz™ is currently producing the upgraded HotShot™ Pro Filling Machine. The HotShot™ Pro can run thicker oil and comes with extra attachments to make filling carts easier than ever.

| A-10 Manual: | Download |

| Dimensions | 18" x 12" x 18" / 45.7 cm x 30.5 cm x 45.7 cm |

| Oil Tank Capacity: | 1 Liter |

| Fill Size: | 0.02 - 1.10 Milliliters |

| Voltage: | 110 Volts |

| Power Cable Length: | 3 Feet / 0.91 Meters |

| Shot-Size Accuracy: | 0.02 Milliliters / 0.02 Grams |

| Cycle Switch Cable Length: | 3 Feet / 0.91 Meters |

| Item Weight (w/ all accessories): | Approximately 28 Pounds / 12.7 Kilograms |

| Manufacturer: | Cooljarz™ |

| Origin: | Factory Direct: Made In USA |